The Science Behind the Success

Our History

Clean Works was born out of a challenge with apples whereby an entire lot of caramel apples had to be removed from retail shelves causing frustration and financial strain for Ontario apple grower, Paul Moyer. Through a joint venture partnership with a global manufacturer, Clean Works was founded.

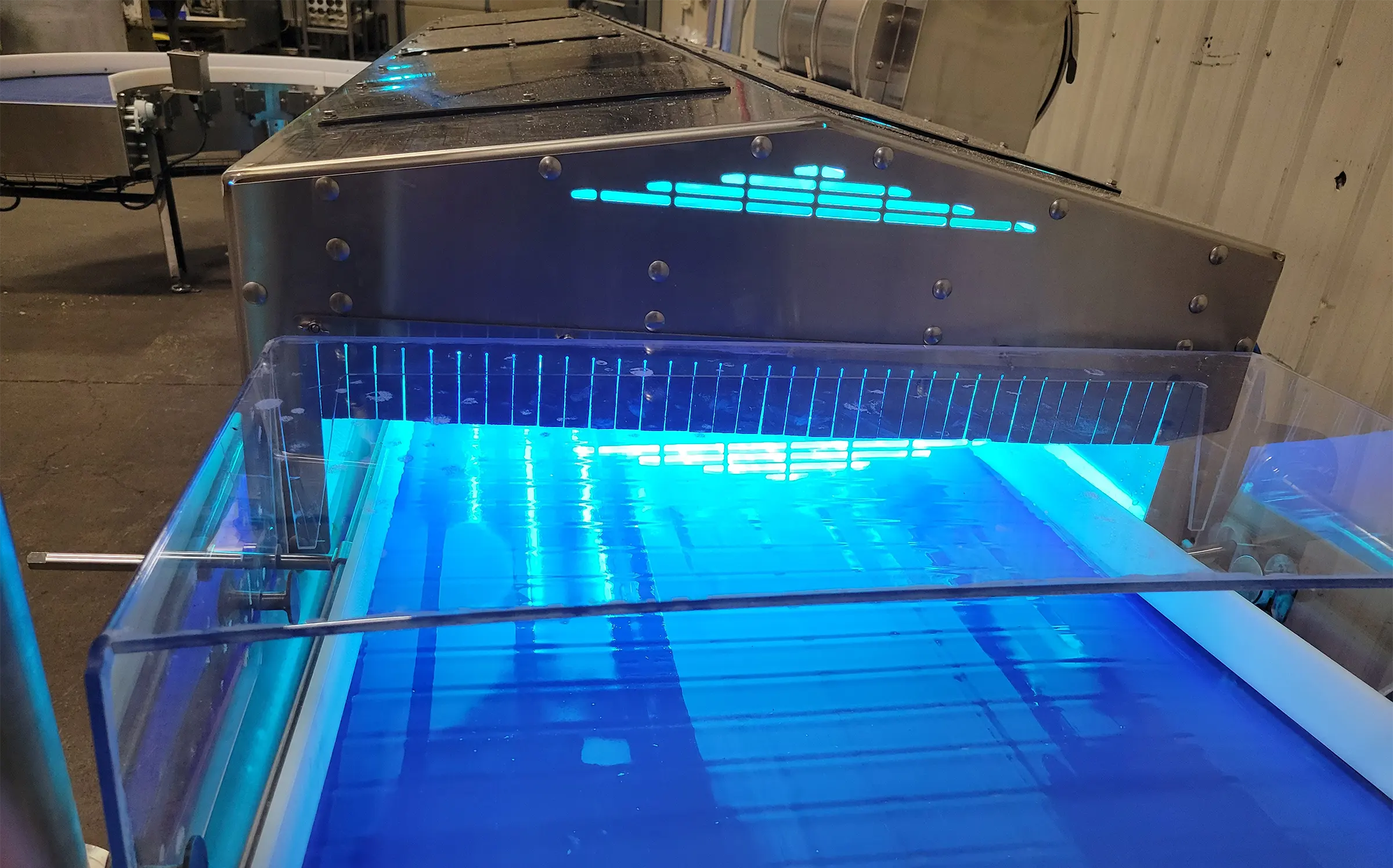

We began our innovation journey focused on pre-harvest to post-harvest solutions, which led to the development of our award-winning, gas-phase homogenous technology. Our innovative technology has been rigorously tested, consistently demonstrating its effectiveness in eliminating up to 99.99% of pathogens and food-spoiling organisms, ensuring produce and packaging is safe and fresh.

This proven technology now expands beyond produce to other industries such as proteins, reusable packaging, production lines, and healthcare. We have also expanded our borders, successfully commercialized our technology in seven countries where we are making a global impact.

Our Customers

The Clean Flow Process reduces pathogens by up to 4 log (99.99%) on produce, proteins, and products. The Clean Flow Process is ideal for larger volume applications, such as packers, processors, and wholesalers, and requires minimal operator intervention. The machine can be customized to work with your existing production lines, workflow, and capacity for all kinds of produce, proteins or products, For example, the Clean Flow process takes less than 30 seconds and can decontaminate 10,000 pounds of produce per hour.

“Clean Works is the future of food safety—the great thing about it is the future is available today. I know it sounds cliche, but it’s true. I currently have Clean Works systems in my facility, and they are irreplaceable.”

“This is a clean, healthy dish ready to serve, and we use Clean Works to ensure that consumers are able to easily use a safe and clean product right out of the package. The peace of mind Clean Works helps us to provide in the ready-to-eat space is invaluable.”